Introduction

Hydrogen is a well-known alternative energy carrier and 360°KAS has been providing hydrogen production related analytical solutions for many years! Independent from which production method our customers use. Whether it is Steam Methane Reforming (SMR), Autothermal Reforming (ATR), Shell Gasification Process (SGP) or electrolysis. We are skilled at the particular process in order to provide the best analytical solution in hydrogen measurement.

Hydrogen quality

As process analysers meant to reveal what is happening in your plant in the real time, analytical solutions are applicable to any kind of the hydrogen production process. This is the crucial information for the control and the performance monitoring of any process.

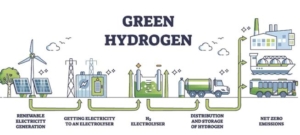

Green hydrogen generation, known as an alternative energy carrier, is still in a pioneering phase but investments are increasing rapidly. The production processes still need to be fine-tuned. Therefore, analysis, data storage and management are key to fully understand hydrogen, its generation process and its conditioning.

When producing “green” hydrogen, it needs to be made sure that the water entering the electrolyser is of the highest purity. For the reason that it correlates directly to the purity (quality) of the produced hydrogen.

“Green” hydrogen gas is produced by splitting water H2O, into hydrogen H2 and O2 oxygen with the aid of electricity. To acquire the highest hydrogen purity and the highest efficiency in terms of electricity consumption and the balance of plant, the quality of the water used in the electrolysis process is of key importance. This purity is used, for instance, for fuel cells (ISO 14687).

360°KAS has the knowledge and experience to guarantee the most optimal results through:

- Customised analyser systems to measure chemical parameters of ultra-pure water.

- Knowledge of key chemical parameters for electrolysis and how to measure these accurately 24/7.

- Supplying the most reliable and efficient water treatment systems required for your process. Ranging from either an alkaline, PEM or SOEC

Hydrogen analysis

The analysis of hydrogen impurities in a gaseous state is not a new topic, as it has been a mature technique for many years. The availability of various analysers on the market indicates that. The usage of hydrogen in (petro) chemical industry has spun market of the online analysers. These analysers can also be used for “blue” hydrogen (traditional generation with CCS), “green” hydrogen generation (electrolysis) and for complying to fuel cell standards (e.g. ISO 14687).

In these cases, online analysers are used to monitor the process. To determine if the conversion to hydrogen is running properly. In these processes, analysers can monitor the hydrogen concentration together with its (unwelcome) byproducts. Analysers can therefore provide useful performance data, also for the hydrogen extraction via e.g. the Pressure Swing Adsorption technology (PSA).

We offer various solutions for the analysing and sampling of alternative energy carrier Hydrogen.

Our Offering

Analyser systems for hydrogen plants

The Shell Gasification Process (SGP) is sometimes considered as “the new kid on the block” in hydrogen production, while 360°KAS has been supplying analytical solutions for this process since 2008! As 360°KAS, we have the independence, knowledge and experience to apply the best technically suitable and economic analyser solution for your hydrogen application.

Sample Conditioning for Hydrogen Analysers

360°KAS is able to meet the stringent requirements that hydrogen sets for any (analyser) sample conditioning: in Zone 1 and Zone 2 hazardous areas; with the smartest and most maintenance free components; lowest achievable lag time and the lowest dead volumes. We have ample experience in building explosion safe equipment for hydrogen rich environments.

Vent Gas Recovery Systems (VGRS)

When using a standard vent gas recovery system for a hydrogen application, you will run into difficulties as several components require some adjustments to ensure proper and safe work. Not paying attention to special demands hydrogen poses to your recovery system, could mean that pressure would drift over the long term (hence your precious analytical results). Not to mention that a hydrogen leak can appear and cause hazardous situations due to unsuitable sealing. At 360°KAS, we know how to handle hydrogen, and can design systems that will allow you to capture and utilize this subtle molecule to its full potential.

Pure Water Chemical Analyser Systems

In a production of the Hydrogen by means of electrolysis, ultrapure water plays key role. Measuring conductivity, as one of the most important parameters, is more difficult than it seems. When the water is almost free from any impurities, it becomes a magnet for anything that it can attract. Just the tiniest addition and/or absorption will have a great influence on the measured value, making not only the measuring sensor quality important, but also the applied sample conditioning components, materials and connections. Based on the experience and deep expertise of Watcon and 360°KAS, we can offer you fit-for-purpose solution.

CLIENT SUCCES STORY

360°KAS awarded for largest renewable hydrogen plant

Our innovative team is responsible for the design, construction and supply of an analyser package for the largest renewable hydrogen plant of Europe. The analyser package includes several analyser systems for pH/Conductivity/H2/N2/O2/H2O and TOC analysis with associated sampling systems.