Introduction

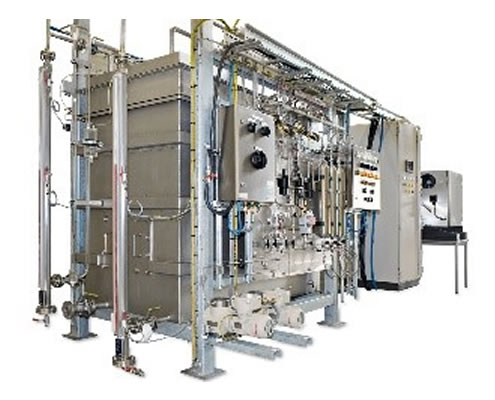

Our automated Continuous Water seal (Dome) sampling system is based on the ISO 8943 and ISO 10715 requirements. It eliminates sample contamination by ambient air via a closed tank construction.

The key feature of our product is that we obtain representative samples from the cryogenic flow in the main LNG transfer pipeline. At first, the continuous water seal (dome) LNG sampler system stores the sample in a water sealed tank. Thus eliminating sample contamination from ambient air. After completion of the sample sequence, the sample is collected in transportable cylinders in accordance with the ISO 8943 paragraph 4.2 Continuous sampling.

We typically supply a LNG Sampling System in combination with:

- A sample take-off assembly

- A LNG probe and vaporiser/accumulator system like the CryoSamp (> 0.7 barg) or our solution for higher line pressures (> 2.5 barg);

- An Intelligent Quality Reporting Module (iQRM)

- Sample transport lines

360°KAS has a long track record in the development and design of Continuous and Intermittent LNG Sampling Systems since 1994. The systems are in compliance with the ISO 8943, the ISO 10715 and the guidelines stipulated in the GIIGNL.

Please download our LNG brochure for more information. In case you have any queries regarding this topic, kindly contact us via +31 (0)85 303 23 00 or info@360kas.com.

Client Succes Stories

LNG Sampler at Oman LNG L.L.C.

The in 1998 installed LNG Dome Sampler from at the OMAN LNG facility in Sur, Oman was exchanged by 360°KAS to full satisfaction of the end user.

Achievement in Waterseal LNG Sampling System

A succesful FAT at Indonesia’s largest oil & gas companies.

Features

- In accordance with ISO 8943 (2007) and flushing & filling of Sample Cylinder in accordance with ISO 10715;

- Sample Holder (Dome) is mounted in a fixed position, so no wear and tear on moving parts

- Outer tank has a closed construction which is flushed with vaporised LNG, so water is not in contact with ambient air, thus eliminating sample contamination from ambient air;

- Continuous sampling method. Continuous flow to sample holder (Dome), Time Proportional or Flow Weight Average to the loading flow;

- With Electric Sample pump(s) for filling the transport cylinders from the sample holder (Dome);

- Optional a 2nd Electric Sample pump (Standby) can be included, so that in case of failure of the Duty Electric Sample pump, transport cylinders will be filled and sample will be available for analysis;

- Requires space of approximately (L x D x H): 2.000 x 1.500 x 2.500 mm;

- Cylinder contains no moving parts.