Introduction

Analyser and sampling solutions are engineered systems used in industrial processes to measure, analyze and monitor properties of gas and liquid streams. 360KAS supplies analysers for all applicable measuring principles: gas, liquid, oil, water, vapor, condensate.

Our Offering

Integrated Analyser Packages

Total analyser package solutions for i.e. Continuous Emission Monitoring System (CEMS), Delayed Coking Units (DCU) and Boiler Feed Water (BFW). Also for any other process unit where analyser measurement is integrated in an enclosed air conditioned solution. Including i.e. sample conditioning in Ex environment.

Continuous Emission Monitoring System (CEMS)

A Continuous Emission Monitoring System (CEMS) is an integrated system used for the continuous measurement of pollutants. Specifically pollutants such as NOX (NO+NO2), CO, THC and Particulate Matter (PM). CEMS are most commonly located in the exhaust stack or vent of industrial plants. Where flow, pressure and temperature are measured in conjunction to determine emissions in pounds/hour or tons/year. In essence, CEMS are required to prove compliance to emission regulations to environmental control authorities.

Sample Probes

Probes extract a representative portion from a gas or liquid pipeline flow for spot and/or continuous composite sampling. A well-designed sample gas probe has no dead volume space. Above all, it should also reduce the required sample volume to limit sample time and ensure a faster response time. Sample probes should be inserted into a process pipeline to 1/3 to 1/2 of the pipeline diameter. This is to ensure a representative sample free of unwanted contaminants that may have collected on the interior pipe wall.

(Ex) Sampling Systems

Customised or standardised analyser sample conditioning systems for i.e. H2S and pH. And for conductivity analysis build on a free standing rack or cabinet enclosure for either General Purpose or Zone 1 or 2 Ex application.

Power-Pye®

The 360°KAS Pyrolysis Sampler is specially designed to sample a gas and to remove solids, water, and/or heavy oils from a complex, hot hydrocarbon vapor mixture. As a result, the clean gas stream can be used for further measurement by a gas chromatograph or a continuous gas analyser.

Product Sampling of oil, gas or condensate

Our product sampling systems are custom designed to withdraw, prepare and store samples. For gas as well as for condensate, crude oil, refined product and LPG.

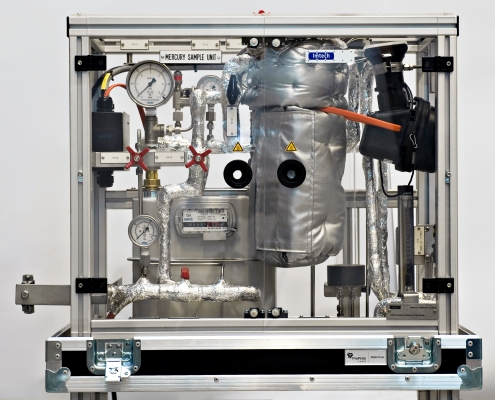

Sampling System for Mercury Analysis

The 360°KAS Mercury Sampling Systems are specially designed to take samples from High Pressure Gas Lines. Therefore, it obtains a representative sample for measurement of Mercury by amalgamation on gold/platinum alloy in accordance with the ISO 6978-2:2003.

Our Extensive Solutions

We have extensive knowledge of production processes, sample take-off, sample preparation, sample storage and applicable analyser measurement principles. Thanks to our long-time experience, 360°KAS provides you with a fit for purpose and trustworthy solution. From conceptual design up to assembly and integration on site, we supply solutions that contain:

- Analysers for all applicable measuring principles (CEMS, gas and liquid, including water)

- Sample Probes

- Sample Conditioning Systems and Sample Pre-conditioning Systems for gas and liquid sampling

- Sample Recovery Systems for vapor & gas (VGRS) and liquid (LRS)

- Analyser Enclosures, Shelters & Houses and (Ex-proof) HV/HVAC systems

- Safeguarding, process safety and process reliability

- Analyser Management And Data Acquisition Systems (AMADAS)

- Product Sampling of water, oil, gas or condensate

- Pye Gas Sampling

- Pump systems (water and HC liquids)

- Storage, control, filtration/separation handling systems (gases and liquids incl. water)

We specialise in providing this equipment for hazardous explosive atmospheres according the ATEX directive 2014/34/EU. As well as pressure equipment in line with ASME design codes and PED 2014/68/EU compliance.